Research and development

Research themes

We conduct a broad range of commercially funded and non-profit research projects on themes such as:

- accident and incident investigation

- large-scale and medium-scale spontaneous combustion testing

- frictional ignition testing

- mine explosion propagation and suppression testing

- mine escape vehicle navigation systems

- emergency response technology.

Simtars' highly trained R&D staff have a wealth of experience in mining safety technology and systems. We have specialist, purpose-built laboratory and testing facilities to deliver high-quality testing and research.

Accessing our research

We publish most of our research in scientific and industry journals, conference proceedings and technical reports, and seek to disseminate our work to industry. The Simtars resource library has an extensive mining library collection that can be accessed by appointment by government, academic and industry-based clients.

Collaborative research projects

Simtars can work with you to deliver collaborative projects and tailored research activities, including the design and implementation of scientific/technical test programs. To date we have worked on numerous industry-shaping investigations, and continue to work alongside industry leaders on ground-breaking research and development projects and themes. Some of these include:

- post-disaster mine navigation

- survivability of equipment post disaster

- testing of innovative shotcrete products

- underground inertisation monitoring

- stonedusting methods

- mine escape vehicle navigation system

- underground communication and telemetry

- collision avoidance and proximity detection technology.

Please contact us to discuss your proposed research project or activity.

Current research activities

Accident/incident investigation and simulation

Our team investigates the root cause of accidents and incidents for use in coronial enquiries and for organisational reviews of processes, procedures and training activities. Our activities include collating and presenting information/facts and providing 3D computer-generated simulations where required.

We have delivered investigations for the Queensland Mines Inspectorate, other public sector organisations and private industry. Past investigation examples include examining the interaction between human and mechanical equipment, and failure of equipment and processes.

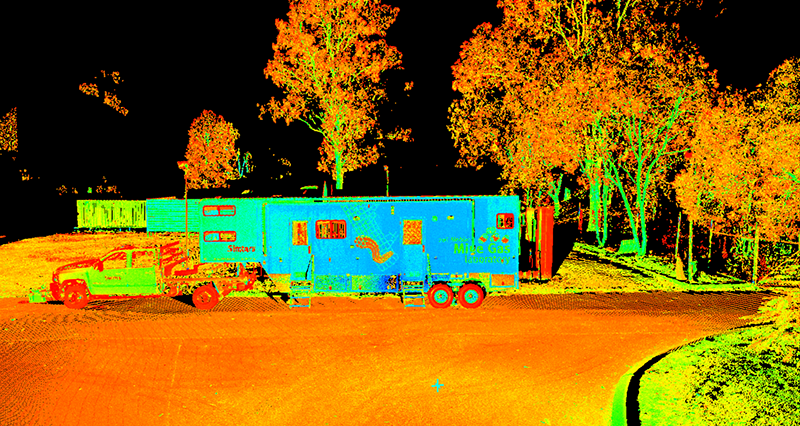

The team utilise 3D point cloud laser scanning technology to capture scenes.This information is used to create a digital representation of a scene or environment that can be subsequently used for accurate measurement and visualisation.

Contact us for further information.

Coal dust explosion prevention and suppression

The Simtars R&D team can simulate coal dust and gas explosions using our 30-metre explosion propagation tube. Results are used to better understand the mechanisms of explosions, to help formulate controls and reduce further explosion occurrences in coal mining. Examples include testing of alternative suppression materials, explosion barriers and equipment survivability.

Frictional ignition testing and investigation

We conduct frictional ignition testing, comparing either pick materials or rock samples, to help prevent disastrous coal mine incidents.

Using a test rig, static rock samples are struck by a modified pick or striker tip to determine propensity for ignition. Testing can be undertaken in open air or sealed environments to further assess the variables of temperature and gas type on the ignition result.

Mine inertisation

We conduct research into mine inertisation, which is used to prevent and suppress underground mine fires. Regular investigations are undertaken by the R&D team to improve industry control measures and simulation software. This includes researching current technologies and equipment and providing recommendations for best use.

We are presently investigating the Steamexfire 300 unit, which generates large volumes of inert gas to control a mine's atmosphere and prevent or extinguish fires. This includes ongoing research with the Steamexfire 300 to meet specific mine site requirements.

Collision avoidance and proximity detection

The research team is currently testing proximity detection systems for use in underground coal mines at Glencore's Baal Bone mine west of Lithgow.

The aim of the testing is to provide the underground coal mining industry with an independent comparison of proximity detection systems available in the market.

The testing program involves subjecting the technology to a suite of scenarios to represent common operational interaction between mine machines and personnel in underground mines.

Typical mine machines include a continuous miner, shuttle car and load haul dump vehicle. This work is being delivered as part of The Australian Coal Industry's Research Program (ACARP).

Mine machine radar project

In collaboration with CSIRO, the research team carried out successful underground trials of the mine escape vehicle (MEV) at New South Wales, Centennial Newstan mine in 2017. The MEV project was originally established in 2002 in response to the Moura No 2 mine disaster in 1994. The 2001 Level One exercise at Kestrel Mine demonstrated the need for the project when the Queensland Mine Rescue Service (QMRS) and the incident management team were unable to respond to survivors deep underground.

A new project funded by ACARP is currently underway to develop the technology into a prototype system using radar technology to enable vehicle navigation in low or zero visibility. The system must enable an underground mine vehicle to be driven in the presence of high volumes of smoke or dust.

Last updated: 11 May 2022