Mineral Mines & Quarries Inspectorate | Bulletin | No.209 V 1 | 25 January 2023

High speed bearing fires on underground loaders

What happened?

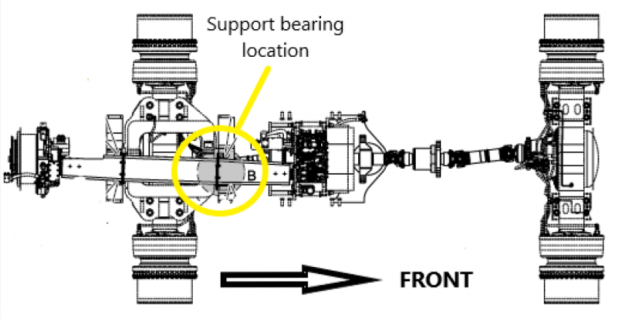

In the last 12 months, there have been five fires involving the high-speed (drive shaft) bearings on underground loaders in Queensland metalliferous mines. These have occurred across different mines, with some mines having multiple fires (refer to Figures 1-5).

Although no one was injured in the incidents, the fires had the potential to cause significant adverse effect to the safety or health of workers. One of the fires was unable to be extinguished, causing a mine evacuation and shutdown for several days and total loss of the machine.

How did it happen?

A common cause of the incidents was found to be the overheating of the high-speed (drive shaft) bearing of the loader.

Key issues

Common contributing factors in the incidents were:

- failure of the bearing lubrication, from blockages in grease lines or using grease with the incorrect specification (grease with Molybdenum Disulphide or other solid additives).

- preventative maintenance programs did not identify premature wear or defects in the bearing during inspections.

- preventative maintenance programs did not specify an appropriate interval change-out frequency for the bearing.

- AFFF fire suppression systems had insufficient coverage, as the bearing was covered by a sheet-metal guard.

The Original Equipment Manufacturer (OEM) released a Safety Bulletin in 2018 detailing the hazards of using the incorrect specification grease in high-speed bearings, and actions to be taken immediately.

Recommendations

Mines should:

- ensure grease used to lubricate underground loader high-speed bearings is the correct grease type as specified by the OEM.

- ensure preventative maintenance programs for underground loaders include inspections to identify lubrication failures, premature wear and early signs of bearing failure.

- ensure preventative maintenance programs for underground loaders set an appropriate change-out frequency for high-speed bearings in consultation with the OEM and based on site conditions.

- ensure an effective system exists for the identification, communication and inclusion of OEM safety and service bulletins in the site's preventative maintenance program.

- ensure AFFF fire suppression systems for mobile equipment have been designed and engineered in accordance with relevant standards, such as AS 5062:2022 - Fire prevention and protection for mobile and transportable equipment.

References and further information

- Mines safety alert 388 - 9 March 2021 - Fire on RC drill rig from compressed air system

- Mines safety alert 384 - 15 January 2021 - Explosion in truck cabin from air-conditioning system

- Mines safety alert 369 - 4 December 2019 - Fire on explosive charge vehicle while at charged face

- Mines safety alert 367 - 7 August 2019 - Worker receives flash burns while repairing fuel tank on loader

- Mines safety newsflash - 15 January 2018 - Re-fuelling rear dump trucks

- Mines safety bulletin 158 - 21 November 2016 - Fixed plant and mobile equipment fires on surface coal mines

- Explosives safety alert 63 - 22 January 2013 - Rags on explosives vehicle exhaust cause fire

- Mines safety bulletin 113 - 12 October 2011 - Equipment fires, investigation and response

- Mines safety bulletin 86 - 30 September 2008 - Fires on mine sites

Contact: Rob Henson, Inspector of Mines , +61 7 4745 4114 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database