Mines safety bulletin no. 158 | 21 November 2016 | Version 1

Fixed plant and mobile equipment fires on surface coal mines

Background

Fires on fixed plant and mobile equipment at mines and quarries continue to represent a significant proportion of High Potential Incidents (HPIs) reported to the Queensland Mines Inspectorate. The Mines Inspectorate's concern over the number of equipment fires has been communicated in previous Safety Alerts and Safety Bulletins (reference 1, 2), as well as being identified by the Chief Inspector of Mines (Coal) as one of the Big 9 focus areas at the Annual Mines Briefing held in November 2015.

Fire hazards may present an unacceptable risk to coal mine workers, whether they be machine operators, first responders or maintenance crew. A step change to the management of fixed plant and mobile equipment fire hazards is required to reduce the risk to as low as reasonably achievable.

This Safety Bulletin:

- provides an analysis of surface coal mine fire HPIs reported during 2015

- recommends strategies for reducing fixed plant and mobile equipment fires.

Analysis of 2015 HPI reports

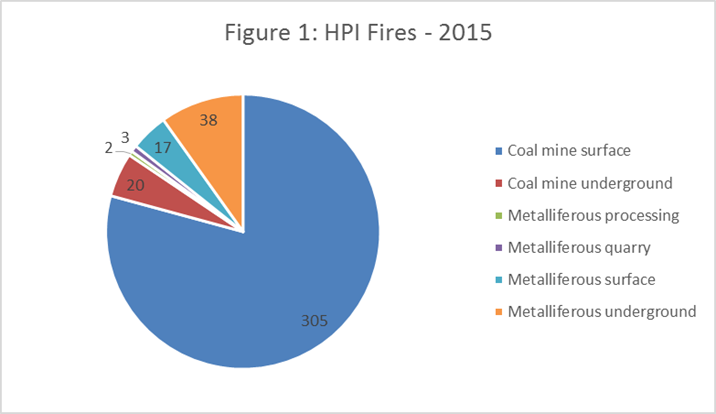

During the 2015 calendar year, 2091 HPIs were reported to the Queensland Mines Inspectorate. Of these 385 were reported as fires (see Figure 1), with 305 fires reported from surface coal mines and over 90% of these fires involved fixed plant and mobile equipment (refer Figure 2 and Figure 3).

Common causes

Common causes of fixed plant and mobile equipment fires reported during 2015 were:

- Electrical: A total of 77 electrical fires were reported of which 60 involved mobile equipment and 17 fixed plant. Common causes identified in incident investigation reports were:

- Modifications to electrical circuits not complying with good engineering practices or standards (e.g. no fuse or circuit breaker fitted to the circuit).

- Worn-through insulation and/or harnesses, looseness of components.

- Battery leads, starter motor, alternator, solenoids.

- Mechanical: Of a total 207 mechanical fires reported, 186 were associated with mobile equipment.

- Fixed Plant: Common causes of fires reported in fixed plant included:

- Delayed maintenance, e.g. a defective conveyor idler bearing was found but it was decided to continue operations and replace the idler on the planned maintenance day. Before this occurred the idler and other associated equipment caught fire causing significant damage.

- Coal fines build-up next to rotating parts, bearing failures, pump and centrifuge drive belt slippage.

Mobile Equipment

Common causes of fires reported on Dozers included:

- Maintenance activities: approximately 20% of reported dozer fires occurred post a maintenance activity such as replacement of blown hoses.

- Blown fuel lines that had not been upgraded as per OEM bulletins

- Hose failures and rub throughs (specifically in the hell –hole and fan drive areas)

- Turbo failures, oil soaked lagging, cracked turbo oil feed lines

Common causes of fires reported on Trucks included:

- Maintenance activities: Approximately 15% of reported truck fires occurred post a maintenance activity such as replacement of blown hoses.

- Re-fuelling systems and practices

- Hose failure, rub throughs (engine bay area)

- Turbo failures, oil soaked lagging, cracked turbo oil feed lines

Common causes of fires reported on Drills included:

- Mast/drill head hoses

- Lack of engine protection

Analysis & conclusions

Analysis of 2015 fires found a broad range of equipment, fire sources and processes involved. No one piece of mobile plant had a particular issue except of dozers, with one brand identified due to its predominant use throughout industry.

Risk assessments

Many site fire risk assessments reviewed were completed at a high level and controls focussed on emergency response and protection methods such as fire-fighting response capability.

Housekeeping

Risks from poor housekeeping standards were sometimes not appreciated. Rags, solvents, waste oil and grease and coal fines caught alight during maintenance at shutdowns, component replacements and in workshops. Failure to clean components after replacing burst fuel lines, hydraulic and coolant hoses caused fires when engine components heated up.

First response

Many reported fires were detected by coal mine workers and controlled proactively using hand held extinguishers or manually activating fire suppression systems.

Mobile plant re-fuelling

Poor re-fuelling practices, typically around field water pumps and lighting plants, and incompatible or poorly maintained fast fill systems on rear dump trucks and excavators figured in a number of incidents.

Maintenance and engineering

Introduction to site

Significant fires occurred on mobile equipment recently introduced to site, including both owner and contractor mobile equipment which was new, recently re-built or with a major component such as an engine replaced.

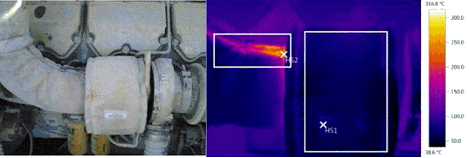

Turbochargers

Many reported turbo fires, after further investigation, are found to be due to other components, such as a hydraulic hoses or fuel lines, failing with flammable liquids being ignited by a hot turbo or exhaust surface. Fires are still occurring soon after turbo replacement. Heat affected oil feed and drain lines disturbed during turbo replacement, or oil soaked components, may catch fire after maintenance.

Workmanship and inspection standards

15 to 20% of fires occurred after a maintenance event. Investigations indicate:

- Incorrectly specified components being fitted (e.g. incorrect diameter hoses not secured)

- Hose clips, clamps not secured correctly

- Hydraulic fitting o-rings not replaced and subsequently leak when hoses replaced

- Areas affected by flammables such as fuel, oil and some coolants not thoroughly cleaned

- Oil soaked lagging not replaced

- Poor fitting of lagging exposing hot spots

- Failure to replace heat affected components such as hoses

- Fire walls, e.g. dozer hell-hole to engine bay area, not re-fitted correctly

- Inspection standards not providing specific guidance on installation standards

- Loose and rubbing components (e.g. hoses and cables, not detected and rectified)

Suggested fire reduction strategies

“Insanity: doing the same things over and over again and expecting different results” Albert Einstein

To reduce the number of fires, a step change in the approach to managing fires is needed, which requires a combination of protection and prevention measures. In addition to current site strategies mines should consider the following if they have not already done so:

Site data analysis

- Analyse site fire reports to identify trends and improvement opportunities to minimise risk of fires.

- Repeat this periodically to assess the outcome of initiatives and refine strategies.

- Apply the pareto principle or similar to identify specific improvement targets.

- Complete specific machine risk assessments and ignition hazard assessment for targeted. equipment, high risk plant or where coal mine workers are exposed to a high risk of fire.

Management commitment and leadership

- Provide focused senior management commitment and appoint a champion to implement fire reduction strategy

- Involve site contractors and partners in the strategy development and implementation

Introduction of equipment to site standards

- Ensure all equipment coming to site, including contractor equipment, meets site fire prevention standards.

Fire risk review

- For targeted plant and equipment, undertake specific fire risk assessments and identify controls based on prevention as well as protection.

- Australian Standard AS 5062:2016 provides guidance on fire protection and the EU directive EN 13463-1 provides guidance on undertaking ignition hazard assessments.

Change management

- Use a change management process and sound engineering principles when fitting after-market equipment to ensure components are correctly rated, compatible and protected.

Alternate products

- Consider alternate products such as approved, non-flammable coolants.

Maintenance strategies

- Review turbo replacement strategies. Life cycle analysis should be undertaken to make sure a best for business replacement strategy has been adopted.

- Consider replacing oil feed and drain lines, seals and lagging associated with the turbocharger when it is replaced, as heat affected lines which have been disturbed or oil soaked components often catch on fire after maintenance.

- Consider proactive replacement strategies based on service life of critical components (e.g. hoses).

Workmanship & inspection standards

- During maintenance, clearly define and appropriately resource the scope of repair work. Clearly specify the standard to be met before equipment is returned to service. Examples include:

- Use correct specification hose (including outside diameter), ensure correct size clamps are fitted and secure, hoses and cables are not rubbing or separated with swivel clips or similar.

- Areas affected by flammables such as fuel, oil and some coolants are thoroughly cleaned.

- Oil soaked lagging is replaced and there are no exposed hot spots due to poor lagging fitment.

- Replace adjacent heat affected components such as hoses.

- Fire walls (eg dozer hell-hole to engine bay area) are correctly fitted.

- Consider targeted inspections of high risk components and installations. Photographs of the acceptable site standard of installation are beneficial.

OEMs

- Involve OEMs in fire investigations and report equipment fires to the OEM.

- Ensure an effective system is in place at the mine to capture and action OEM service bulletins.

Fire prevention implementation – Operations feedback

Mines which have implemented a structured approach to fire reduction over the last two years have reported positive results, two sites achieving a reduction of HPI fire reports of around 60%. Reduction in fires has significant consequential benefits to safety, productivity and costs.

References and Guidance Information:

- Safety Bulletin No.113, 12 October 2011; Equipment fires, investigation and response, Queensland Mines Inspectorate

- Safety Bulletin No. 86, 30 September 2008; Fires on mine sites, Queensland Mines Inspectorate

- Safety Bulletin No: SB 13-05 Too many underground fires, NSW Trade and Investment, Mine Safety

- NFPA 122: Standard for Fire Prevention and Control in Metal/Nonmetal Mining and Metal Mineral Processing Facilities

- FM Global datasheets

- Australian Standard AS 5062:2016 Fire protection for mobile and transportable equipment.

- EN 13463-1 Non-electrical equipment for use in potentially explosive atmospheres – Part 1 Basic method and requirements

Contact: Anthony Logan, Inspector of Mines , +61 7 3199 8013 anthony.logan@dnrm.qld.gov.au

Issued by Queensland Department of Natural Resources and Mines

Find more safety notices

Search the hazards database