Petroleum & Gas Inspectorate | Alert | No.113 V 1 | 23 February 2023

Gas cooktop connecting elbow failure

What happened?

The inspectorate is concerned about recent failures of gas cooktop connecting elbows. The elbows are supplied with gas cooktops and used to connect the appliance to consumer piping.

Failures from cracking and in some cases complete failure have resulted in gas leakage. At this time there has not been any injury or property damage.

How did it happen?

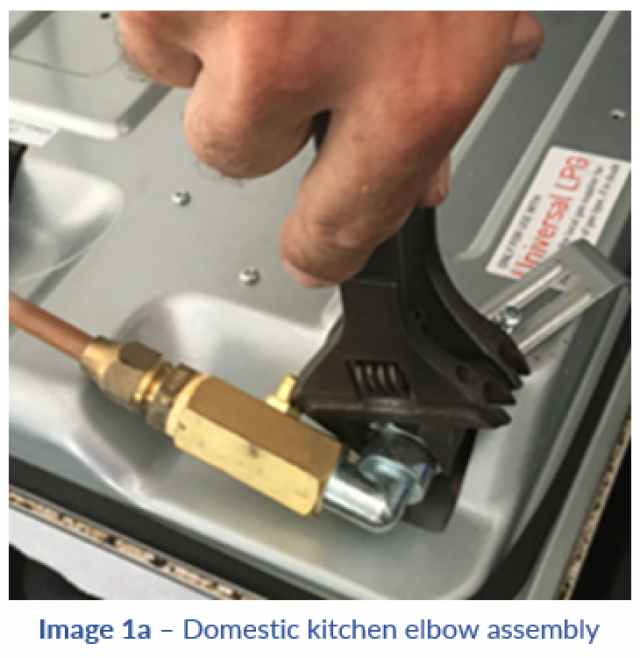

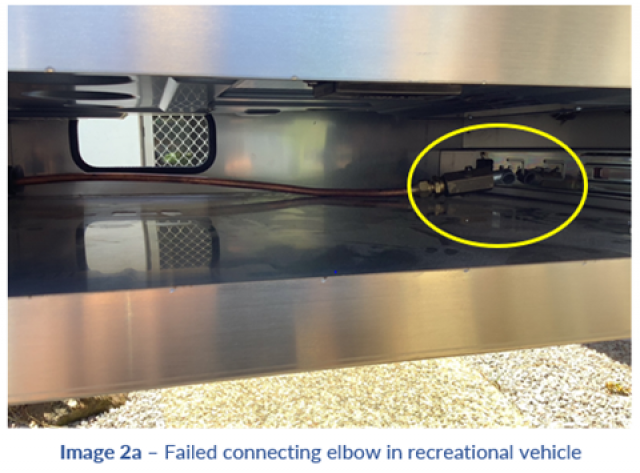

The incidents of failure have occurred in both domestic kitchen installations (see Images 1a and 1b) and recreational vehicle slide out kitchen installations (see Images 2a and 2b).

Initial information suggests causal factors include installation practices that result in the connecting elbow being subjected to excessive stress, strain, and accelerated material fatigue, ultimately resulting in failure and the potential of gas leakage.

Causal factors include:

- Excessive torsion when making and tightening gas joints, resulting in strain and fatigue being created within the material of the fitting.

- Not providing adequate support of consumer piping, resulting in strain and vibration being transferred into the fitting.

The inspectorate is raising concerns with gas appliance manufacturers and Australian standards in relation to the design, material and suitability of the current component design.

Key Issues

- Explosions and fires can be caused by igniting leaking gas.

- Fittings (connecting elbow) are failing and causing gas to leak.

- Failure of elbows may be caused by stress, strain or accelerated material fatigue.

Recommendations

- Installers should ensure connecting elbows are correctly located and orientated and that joints are not subjected to stress or strain by overtightening.

- Installers should ensure that consumer piping is adequately supported and that connecting elbows are not subjected to stress or strain.

Note: This is critical in recreational vehicle gas systems due to the potential of vibration during travelling.

- Installers should check connecting elbows of appliances they service or repair for gas leakage, signs of cracking or fatigue.

Note: Where leak detection fluid is used, any residue should be removed to avoid any future chemical reaction and damage.

- Gas appliance manufacturers should ensure where required, adequate information is included within the instructions to correctly assemble, position and tension joints connecting appliances to consumer piping.

- Gas system owners should check for visual signs of cracking and if concerned contact a gas installer (Gas Work Licence holder).

- If you smell gas, turn off the gas supply, ventilate the area and call a gas work licence holder.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

References and further information

- AS/NZS5601.1 – Clauses 2.2.3.5 and 5.8

- AS/NZS5601.2 – Clauses 2.7.4 and 5.2.11

- Petroleum and Gas website. Petroleum and gas safety and health | Business Queensland

- Consumer safety website. Gas safety | Emergency services and safety | Queensland Government (www.qld.gov.au)

- Currant Queensland legislation: In force legislation - Queensland Legislation - Queensland Government

Contact: Paul Beaumont, Principal Inspector, Gas Work , +61 7 5459 6189 paul.beaumont@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy.

Find more safety notices

Search the hazards database