Mines safety bulletin no. 191 | 25 October 2023 | Version 3

Managing heat exposure in coal mines

BACKGROUND

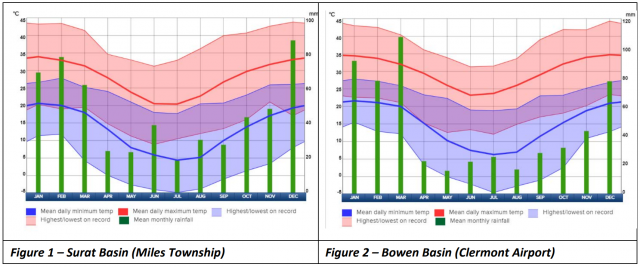

Each year during the period between October and March the average ambient outdoor temperature typically climbs above 30°C and this increases the risk of heat exposure at all Queensland coal mines (Fig 1 & 2). At the beginning of this period, persons with safety and health obligations should review the mine’s preparedness for managing heat exposure and communicate with coal mine workers, how exposures are to be managed. These obligation holders must ensure that exposures to heat are being effectively managed to an acceptable level of risk at their mine sites.

The mine's safety health management system (SHSMS) must incorporate processes to recognise and effectively manage heat exposure and to protect coal mine workers (CMW) from heat related illness.

IDENTIFICATION

When identifying hazards associated with heat and the onset of heat-related illnesses, the following risk factors should be taken into consideration:

- air temperature and humidity

- amount of air movement e.g. natural and forced

- radiant temperature of surroundings e.g. environment, plant and equipment

- clothing breathability e.g. inhibits the evaporation of sweat

- physical manual work e.g. metabolic heat load, type and duration

- acclimatisation status of worker(s) (recent exposure to working in heat)

- hydration level of workers

- fitness level of workers.

ASSESSMENT

Thermal conditions in the mine can change daily, the risk factors (above) also change and not all CMWs respond to heat in the same manner. These factors must be taken into consideration when assessing the heat exposure risk. A risk assessment will assist in determining the severity of the heat exposure, action required, whether the existing control measures are adequate and what action should be taken to control the risk to an acceptable level.

The use of Effective Temperature is prescribed for use in the heat stress assessment process applied in underground coal mines due to the unique conditions in that environment. There are several other heat stress indices available which can be considered for use in open cut surface mines. These include but are not limited to Wet Bulb Globe Temperature (WGBT), Predicted Heat Strain (PHS) and Thermal Work Limit (TWL). The selection of which heat stress indices to use should be determined based on the specific factors relating to the site and conditions. In some cases, a combination may be required.

The following resources provide readily available information, assessment tools and processes for the assessment of heat exposure and heat related illnesses:

- Heat Stress Calculator - Worksafe Queensland.

- A Guide to Managing Heat Stress: Developed for Use in the Australian Environment - Australian Institute of Occupational Hygienists (AIOH).

- Managing the Risks of Working in Heat Factsheet - Safe Work Australia.

- Working in Heat - Safe Work Australia

CONTROL

The approaches taken when selecting controls for implementation include modifying the environment to suit the work, modifying the work to suit the environment or a combination of both. The following controls should be considered:

- Reduce radiant heat sources using insulation, spot cooling or shielding.

- Locate potable water and ice machines within easy access for workers to hydrate regularly.

- Use mechanical aids where possible (e.g. using cranes and forklifts), to minimise physical exertion in heat.

- Plan work activities to include periods of acclimatisation for workers returning after prolonged absence.

- Implement regular rest breaks in cool areas such as vehicle cabins, crib rooms and control rooms.

- Erect portable shades as refuge areas for temporary or remote work locations

- increase air movement by the installation of mechanical fans and introduce cooling fans where possible.

- Reschedule high physical work activities to cooler times during the shift.

- Select clothing options which offer ventilation openings and permeable fabric.

- Introduce a buddy system and/or task rotation.

Consideration should be given to the development of triggered action response plans (TARPs) for controlling heat exposure on a shift by shift basis. The action trigger values should be aligned to local heat conditions such as Effective Temperature (ET) in the underground environment and ambient air temperature in surface operations. Forecasts from the Bureau of Meteorology provide a useful indication of thermal conditions in outdoor surface environments for use in TARPs.

RECOGNISING SIGNS OF HEAT ILLNESS

The human body has a thermoregulatory system which maintains a constant internal core temperature even when exposed to varying environmental conditions. When the body's core temperature exceeds 37°C, it reacts by increasing the blood flow to the skin, thus producing sweat that cools the body when it evaporates. Most people feel comfortable when the air temperatures are between 20°C and 27°C and when the relative humidity ranges from 35 to 60 per cent. Workers may feel uncomfortable when air temperature or humidity is higher than this. When exposure to heat exceeds the body's capacity to maintain hydration and thermal balance, heat related illness can occur.

CMWs should be trained to recognise the signs and symptoms of heat related illnesses and to take preventative actions to prevent illness or injury. Heat related illness can take several forms including:

| Symptoms may include: | |

|---|---|

| Prickly Rash | Itchy skin rash with raised red spots which is caused by the sweat ducts becoming blocked. |

| Fainting | Giddiness and fainting, resulting from prolonged standing, or physical exertion in the heat. |

| Cramps | Muscle cramping resulting from inadequate replacement of salts lost during excessive sweating. Common among CMWs that are not acclimatised to performing work in heat conditions. |

| Exhaustion | Fatigue, nausea, vomiting, clammy skin, and weakness with elevated body temperature. Heat exhaustion may progress to heat stroke if exposure to heat continues without treatment. |

| Heat Stroke | CMW may appear disorientated and confused, may encounter convulsion episodes, or become unconscious. Skin appears hot and dry. Life threatening condition. Treat as medical emergency. |

MANAGEMENT OF HEAT ILLNESS

The SHMS must provide for first aid facilities and emergency response capability at a mine; that is suitable for responding to cases of heat illnesses caused by exposure to work in the heat. First aid officers should be trained on how to recognise the signs of heat related illnesses and provide effective treatment in a timely manner.

LEGISLATIVE REQUIREMENTS

The Queensland Coal Mining Safety and Health Regulation 2017 (CMSHR) sets out specific provisions for both surface and underground coal mines with respect to the management of heat. In summary:

- An underground coal mine's SHMS must provide for:

- ensuring the health of persons in places at the mine where the wet bulb temperature exceeds 27°C [s369(1)]

- a methodology for calculating effective temperature at certain locations [s364 and 370]

- preventing persons from working at the mine where the effective temperature exceeds 29.4°C unless under specific circumstances [s369(3)].

- A surface coal mine's SHMS must include a procedure for protecting persons from heat related illness [s143].

In addition to this safety alert, Recognised Standard 18 - Management of heat in underground coal mines was released in August 2021 and Guidance Note 32 for management of heat at surface coal mines was released in January 2022.

The proper management of heat related illness will require coal mines to use risk analysis techniques to identify the hazards, assess the risk, determine effective controls, and continually review control effectiveness.

REPORTING

All events where heat exposure is a contributing factor should be managed in accordance with the Mine’s Incident Management Process and recorded / reported as a heat related incident (likely classified as an HPI or an LTI). Section 17 of the Coal Mining Safety and Health Act 1999 defines an HPI as an event, or a series of events, that causes or has the potential to cause a significant adverse effect on the safety or health of a person.

Where heat related incidents occur onsite and meet the requirements of section 16 of the CMSHR being; (a) a person suffers an injury – (i) of a severity that requires treatment by a doctor, or a nurse, or a person qualified to give first aid; or (ii) that prevents the person from carrying out the person’s normal duties at the mine it must be reported in the approved form

REFERENCES AND ADDITIONAL SOURCES

- Coal Mining Safety and Health Regulation 2017.

- Heatwave Service for Australia - Bureau of Meteorology.

- Heat Stress - Managing Exposure - Worksafe Queensland (2017).

- Safety Bulletin 115 - Risk Management of Heat Exposure in Mining

- Safety Bulletin #91 - Heat Stress

Contact: +61 7 3199 8001 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Find more safety notices

Search the hazards database