Mines safety alert no. 380 | 29 September 2020 | Version 1

Uncontrolled Truck Movement Due to Brake Fade

What happened?

A service truck had been travelling down a ramp. At the beginning of the ramp the service truck has been placed in second gear to control the speed whilst travelling down the ramp. The service truck operator has gone to apply the brakes to further slow the vehicle down. When this has happened the brakes have been ineffective resulting in the brakes not applying. The service truck operator has then steered the truck into a pile of material to stop the truck movement.

How did it happen?

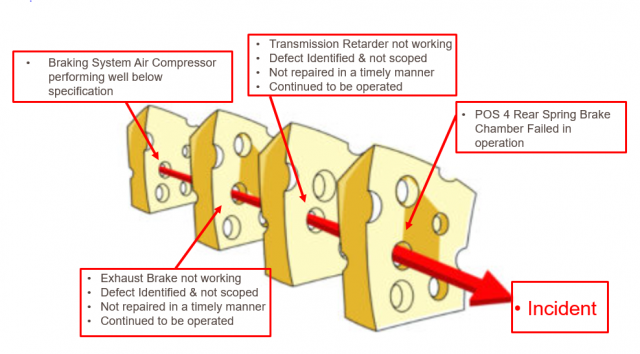

- A spring brake chamber diaphragm had failed in operation.

- The air compressor for the air brake system was performing well below specification, therefore unable to maintain air pressure within the brake system, causing the rear brakes to drag, subsequently overheating and becoming ineffective. (Brake Fade)

- The exhaust brake was not functioning.

- The transmission retarder was not functioning.

- System defects were not identified as safety critical (stand down) defects by the operators.

- Identified defect repairs were not being repaired or scheduled in a timely manner.

Recommendations

All SSEs should review the SHMS to ensure:

- All defects in speed retardation or braking systems on mobile plant are identified.

- All mobile plant with defects in speed retardation or braking systems are removed from service until repairs are completed.

- Maintenance strategies are enacted to ensure air compressors on mobile plant are adequately maintained and warning systems (light, buzzer) are functional and accurate to identify system inadequacies.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

References and further information

Safety Alert Purpose

- Draw attention to the occurrence of a serious incident in the mining industry.

- Increase risk awareness.

- Promote mines to examine and check their controls are adequate.

The investigations are ongoing and further information may be published as it becomes available.

The information contained in this publication is based on knowledge and understanding at the time of writing.

Contact: Michael Scully, Inspector of Mines , 0459 878 917 Michael.Scully@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Find more safety notices

Search the hazards database