Coal Inspectorate | Alert | No.392 V 1 | 09 June 2021

Sudden tyre failure ejects rock shrapnel through a dozer’s cabin

What happened?

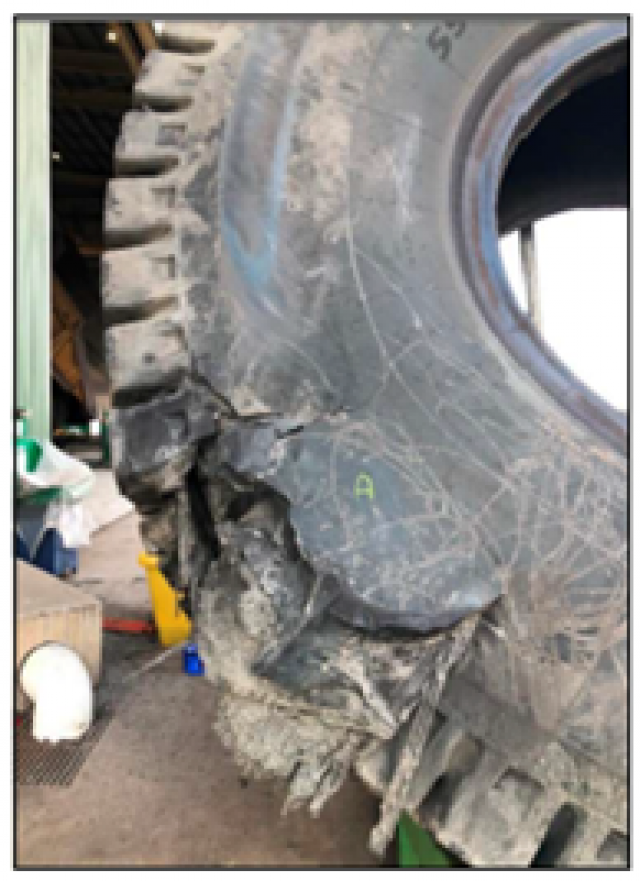

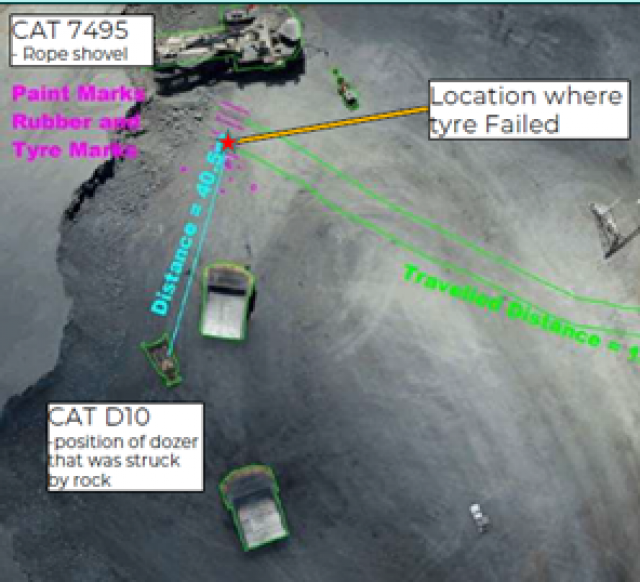

A Cat 795F rear dump was being loaded by a rope shovel when a basalt rock approximately 400mm in diameter has fallen on the offside and rolled beneath the truck unnoticed. Once loaded the truck has driven forward over the rock causing Position 6 tyre to immediately fail (figure 2). This sudden eruption caused numerous pieces of basalt rock shrapnel to eject from the floor, with one rock weighing 950 grams striking a manned Cat D10T dozer parked 40.5 metres away. This rock penetrated the dozer cabin’s right-side window (figure 3) before passing through the cabin and exiting by shattering and pushing out the rear window (figure 4). The rock was later found on the catwalk behind the cabin. The dozer’s operator stated that he was crouched / leaning forward in the dozer’s seat at the time of the impact. The dozer at the time was waiting to conduct floor clean-up and had Impact Rated XIR Glass fitted. Position 6 tyre which was 512 hours old had been inspected earlier in the day as part of preventative tyre maintenance, and no issues were identified.

How did it happen?

As a truck has pulled away from the excavation face a large rock, run over by Tyre Position 6, has immediately caused the failure of the tyre, causing rock shrapnel to eject from the floor.

Key issues

- Basalt can have an unconfined compressive strength of 100-300 MPa.

- High strength strata can cause severe damage to tyres.

- Mining equipment parked in a potential "line of fire".

Recommendations

- Identify restricted work areas near excavation faces.

- Designate safe parking areas for equipment near excavated faces.

- Ensure effective risk management for excavation of high strength material (e.g., basalt).

- Ensure loading techniques minimise spillage.

- Review mining equipment to ensure Impact Rated Glass is fitted where required.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

References and further information

Coal Mining Safety and Health Regulation 2017, section 117 - Spoil Dumps and Excavated Faces

Contact: Peter Currie, Inspector of Mines , 0419 740 820 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Find more safety notices

Search the hazards database