Mines safety alert no. 354 | 04 July 2018 | Version 1

Persons and mobile plant falling over edges

What happened?

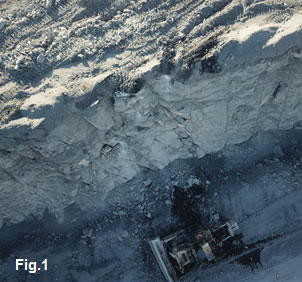

In June 2018 on a surface coal mine, a D11 Dozer travelled over the crest of a highwall while ripping after dark, falling approximately 16 metres onto a lower bench (see Fig.1 below). The dozer also rolled 360 degrees before coming to rest, and the dozer operator was seriously injured.

Approximately twelve months prior to this, an identical incident occurred at another surface coal mine. This time during daylight, a D11 Dozer travelled over the crest of a highwall while ripping, coming to rest about 10 metres below (see Fig.2). In both cases only good fortune prevented a fatality.

How did it happen?

Recommendations

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

Comments

The Queensland Coal Mining Safety and Health Regulation 2017, sect.118(a), requires a mine's safety and health management system (SHMS) to provide for installing safety berms or implementing other appropriate control measures to prevent persons and mobile plant from falling over edges with a vertical drop of 1 metre or more. Mines must have such effective controls in place as going over a pit wall can easily lead to a fatality.

Contact: Creswick Bulger, Inspector of Mines , +61 7 4938 4605 Creswick.Bulger@dnrme.qld.gov.au

Issued by Queensland Department of Natural Resources, Mines and Energy

Find more safety notices

Search the hazards database