Mineral Mines & Quarries Inspectorate | Alert | No.419 V 1 | 19 October 2022

Mobile Plant Reversing into Light Vehicle

What happened?

Two recent High Potential Incidents have involved tracked heavy mobile equipment (HME) reversing into stationery light vehicles (LV).

Incident #1 – Excavator vs LV

- The excavator operator was on the ground relocating a mobile jaw crusher.

- A second worker arrived in a LV and was unable to access the usual LV park-up location due to the presence of an operating front end loader and a dump truck. The worker parked the LV close to, and behind, the unoccupied excavator and exited the LV.

- The excavator operator restarted the excavator to move it to another location and reversed into the unoccupied LV (see figure 1 below).

Incident #2 – Dozer vs LV

- Two dozer operators arrived at the work location in a light vehicle, parked up and commenced dozer operations.

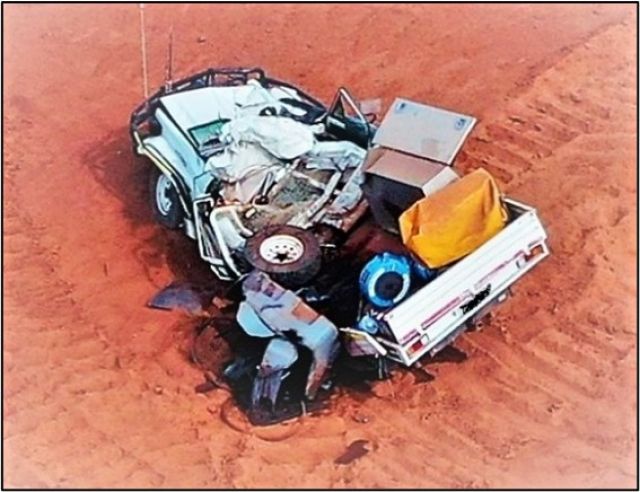

- One of the dozers subsequently reversed onto the unoccupied light vehicle (see figure 2 below).

How did it happen?

- the LVs had been parked within the HME operating zone and the HME operator was aware of their presence

- the HME operators did not ensure that the path of travel was clear before reversing.

- the dozer was not equipped with a functioning reversing camera

- operators were focused on completing tasks as quickly as possible due to production pressures

- operator inexperience

- ineffective supervision.

Key issues

There are many historical incidents involving HMEs reversing into LVs – and in many of these incidents, the critical controls necessary to prevent the collision were absent or ineffective.

A critical control is defined as a control that if removed or not executed exactly as intended, would cause an unsafe situation despite the existence of the other controls.

Recommendations

- Collision avoidance technology-type controls that warn of, or detect, the proximity of threats independent of the operator’s field of vision are implemented.

- The mine design and operations layout provides for designated, safe LV parking locations in operational areas.

- LV parking locations should be routinely inspected and monitored to ensure the location continues to be appropriate and LV are parked in designated parking areas as required.

- Workplace risk assessments ensure workers identify safe locations for impromptu parking when required to park near operational areas in the field.

- All HME and LV operators are trained and assessed to ensure they demonstrate compliance with the correct parking requirements. They must demonstrate an understanding of the risks of parking an LV behind HME and the need to park in designated areas even when HME is unoccupied.

- HME and LV operators must also demonstrate an understanding of HME blind spots prior to being considered competent to operate or park in operational areas.

- Operators do not rely on positive communication protocols. Other actions must be taken that ensures HME cannot interact with LV in operating areas. Eg. Shut down of HME while LV in area.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

References and further information

Guidance Note QGN 27 Collision prevention (Mining and Quarrying Safety and Health Act 1999)

Learning from investigations: Fatal collision between dozer and light vehicle

Contact: Deon Esterhuizen, Regional Inspector of Mines , +61 7 3330 4254 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database