Coal Inspectorate | Alert | No.428 V 1 | 25 May 2023

Coal mine worker seriously injured undertaking conveyor belt repairs – Investigation summary

What happened?

On 7 September 2021 a Coal Mine Worker (CMW) was seriously injured when struck by a section of conveyor belt whilst undertaking repairs to an underground coal mine conveyor belt. This bulletin presents information and learnings from the investigation completed by the Queensland Mines Inspectorate.

How did it happen?

Earlier, during the night shift, the conveyor belt tripped during production. Inspections of the conveyor belt by CMWs identified damaged clips and found the belt to be folded over on itself from the jib pulley and for approximately one pillar inbye. CMWs were allocated to replace a belt clip in the conveyor belt loop take-up area and other CMWs, including the injured CMW, commenced unfolding the belt working from outbye the conveyor drivehead towards the jib pulley.

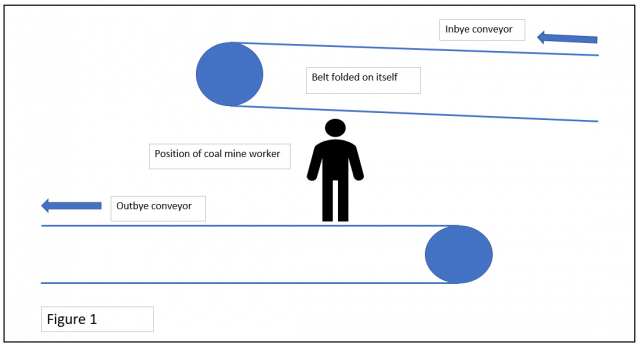

A diagram of the incident site is shown in Figure 1.

The damaged inbye conveyor was suspended from the mine roof and during production transports and transfers longwall coal to the outbye conveyor.

At the time of the incident, the injured CMW was standing on the outbye conveyor belt as shown in Figure 1. He was attempting to unfold the conveyor belting at the jib using pincers and a chain block.

The chainblock and pincers are shown in Figure 2.

Under tension, the pincers came free from the belt causing the belt to flip back. The CMW was struck on the side of the head. He fell, landing on the belt with his arm and upper torso between the guarding and the structure of the outbye conveyor belt.

An emergency response was initiated and the injured CMW was transported to the hospital.

Key issues

The investigation identified that:

- The injured CMW suffered serious injuries that required hospitalisation and ongoing medical treatment.

- No other CMWs were reported to suffer physical injuries.

- The task being undertaken was not a planned job. It was a breakdown repair task.

- CMWs undertaking belt clip repairs at the conveyor belt loop take up followed mine risk management processes.

- Risk associated with being positioned in the "line of fire" of the pincer and chainblock were not assessed and controlled.

- The mine's Safety and Health Management System (SHMS) includes multiple layers of risk management standards and procedures, suitable for unplanned tasks.

- Mine risk management procedures were not followed by CMWs undertaking the belt turnover recovery. No evidence of relevant SLAMs (Stop, Look, Assess, Manage) or JSA (Job Safety Analysis) documentation were identified.

- There was no evidence that CMWs involved in flipping the belt had isolated the conveyor belts. The inbye conveyor belt had not been de-tensioned to eliminate the stored energy in the belt.

- There was no evidence that the pincer had been approved for use as a belt pulling tool.

- It was not clear who was responsible for overall supervision of the belt repair task.

- Multiple supervisors were present at the incident site however no supervisor questioned or challenged the job planning process, including following SHMS risk management processes, risk assessments, lack of isolation or de-energising the belt.

- The nature of the belt unfolding task changed and personnel did not recognise, stop and reassess the change in risks, as the belt became more difficult to flip.

- The Explosion Risk Zone (ERZ) controller was undertaking inspections in multiple districts. It is not clear how the ERZ controller could effectively supervise the safety and health of persons working in the multiple districts.

- No evidence was provided of senior leadership personnel periodically challenging belt recovery tasks. The exception was in relation to the belt clip replacement being undertaken in the loop take up.

Recommendations

All Site Senior Executives (SSEs) should:

- review inspection plans in place at the mine to ensure that adequate and effective supervision is practised at all times based on the activities being undertaken in the mine

- review management structures and clarify supervision requirements and expectations for maintenance and breakdown tasks

- ensure CMWs are familiar with and understand mine requirements for appropriate risk management prior to commencing any repair or maintenance work, including de-energising and isolations of equipment

- implement effective systems that ensure CMWs are diligently complying with SHMS requirements

- review procedures for the introduction of plant to site, particularly the assessment of fit-for-purpose small tools.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

Contact: Anthony Logan, Senior Inspector of Mines (Mechanical) , 0477 373 213 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database