Coal Inspectorate | Bulletin | No.216 V 1 | 26 October 2023

Serious finger accidents at Queensland coal mines

What happened?

Resources Safety and Health Queensland is urging coal mines to be more hands on when it comes to preventing one of the mining industry's most common serious accidents. Since 2021, 55 serious accidents involving fingers have been reported at Queensland coal mines; of these 28 happened this year (2023). A quarter of the reported serious accidents involve considerable risk activities associated with lifting, slinging and towing. Additionally, approximately another 20 high potential incidents involving fingers have been reported.

Serious accidents involving fingers may not be life threatening, however, for those involved they may have a serious impact on their lives even following rehabilitation.

How did it happen?

- On 6 January 2023, a coal mine worker (CMW) at Lake Vermont was installing a gasket between flanges on a fine coal centrifuge while the upper section was suspended from a pendant controlled hoist. The CMW’s finger (and glove) became trapped and was crushed between the flanges when the upper section was inadvertently lowered (refer Figure 1).

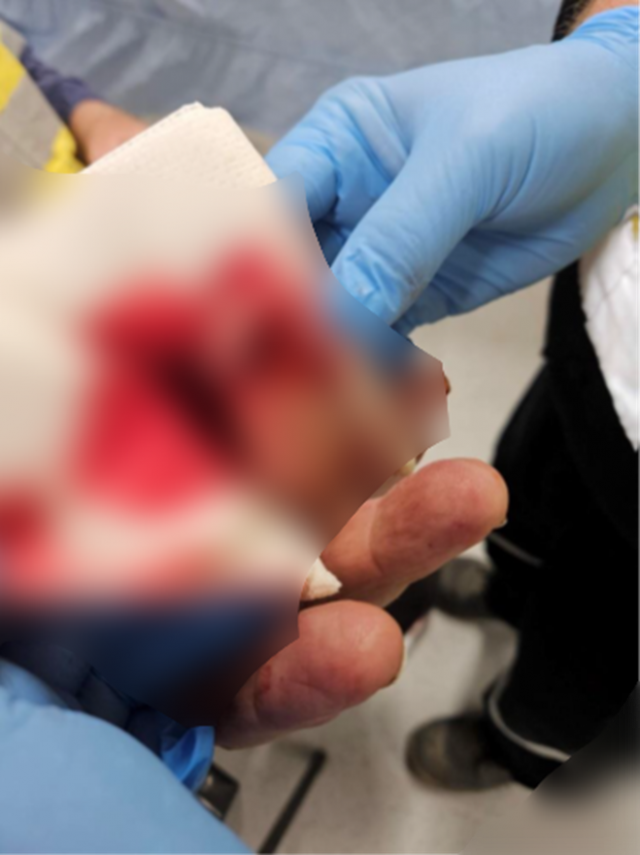

- On 11 January 2023, at Grosvenor a CMW's finger was crushed between the surface drill rig cavin slips and the drill rod when the slips were being manhandled (refer Figure 2).

- On 16 January 2023, a CMW at Carborough Downs driving a LHD in an underground mine attempted to push a redundant hanging chain out of the way. Their left-hand index finger was caught in the chain at the edge of the LHD canopy. As the machine moved forward the CMWs finger was amputated at the first knuckle (refer Figure 3).

- On 8 February 2023, a CMW at Gregory Crinum Coal Mine sustained a deep finger laceration to their left-hand ring finger and a minor laceration to their left-hand middle finger while removing a guard from a deslime screen exciter mechanism. The guard was being lifted from its position using a chain-block when the guard became snagged on the screen structure. The CMW was injured as they attempted to free the guard, with their left hand becoming crushed between the guard and screen structure. The injured CMW required surgery.

- On 10 February 2023, a CMW at Goonyella Riverside was undertaking maintenance work on an excavator track when a loaded cum-a-long hook failed, striking the CMW’s hand. The CMW suffered a compound fracture and lacerations to their right-hand little finger.

- On 17 February 2023, at North Goonyella a CMWs right hand was caught and pinched between two steel beams when conducting maintenance work that involved slinging and lifting. The CMW suffered multiple finger fractures that required surgery.

- On 25 February 2023, a CMW at Rolleston Mine was working on a Cat789 rear dump truck attempting to align and insert the pin through the lateral link/dogbone and chassis when the link has moved with the CMWs finger in the pin housing. This movement has resulted in the severing of the tip of their left middle finger.

- On 8 March 2023, while installing and aligning a longwall crusher, a CMW at Carborough Downs struck their left-hand finger with a sledgehammer which resulted a serious laceration to their ring finger.

- On 10 March 2023, a CMW at Oaky North Mine was conducting maintenance on a continuous miner roof bolting rig. Whilst fault finding issues identified by the operator with the gripper jaws, the CMW activated the jaws from the control bank with their right hand crushing the left-hand index finger.

- On 19 March 2023, a CMW at Grosvenor Coal Mine was filling a LHD with hydraulic oil in the surface workshop. When they disconnected the quick fill fitting from the LHD the CMW caught their finger on the fire suppression support bracket. Fingernail surgery to their right-hand middle finger was required.

- On 23 March 2023, a CMW at Byerwen Mine accessed an excavator house through a hatch door to repair rubbing fire system hoses. The unsecured hatch door closed contacting the CMWs hand which was placed on the hatch surround at the time. The CMW suffered a broken little finger which required surgery.

- On 11 April 2023, a CMW at Carborough Downs was replacing feed chains on a multi-bolter left hand outer bolting rig when the feed carrier fell crushing the CMWs left hand between the carrier and the feed cylinder refer (refer Figure 4). The CMW required surgery to stabilise a finger fractures and lacerations.

- On 23 April 2023, a CMW at Oaky North Mine was clearing a buried longwall AFC Bretby tray after a blockage at the maingate. Rock fell from between the shields, impacting and fracturing the CMWs right index finger.

- On 29 April 2023, at Grosvenor Coal Mine a tradesman using sledgehammer to remove part of a block wall, squashed a finger between the handle of hammer and the concrete blockwork. They suffered a crush injury to the nail bed on left hand index finger which required surgery.

- On 30 April 2023, a Fitzroy CMW was manoeuvring by hand a 125mm hammer drill bit in the tray of a light vehicle utility. While manually moving the object, an adjacent drill stub assembly rolled pinching the CMWs left hand ring finger between the two steel items. Surgical treatment to treat fingernail cuticle damage was required.

- On 4 May 2023, a Daunia Mine CMW undertaking a maintenance task suffered what was considered to be a minor injury to a finger whilst using an Allen key. Three days after the incident they were admitted to hospital for infection treatment by IV antibiotics after reporting finger pain.

- On 5 May 2023, at Clermont Mine CMWs were tasked to carry out the sub replacement on a surface drill rig. They removed the head sub and when refitting the new sub, it was positioned on the hobo. The injured CMW tried to move the sub into the right position by hand, causing the sub to lose balance on the hobo and move in an uncontrolled manner. The CMW has then tried to grab the sub and it has pinched a finger between the sub and the hobo. The CMW suffered a crush injury to their left-hand middle finger.

- On 13 May 2023, at Broadmeadow Mine a CMW was cutting conduit with a handsaw when the saw both gripped and bounced simultaneously resulting in a laceration to the left hand, between the thumb and first finger. The CMW suffered tendon damage requiring surgery.

- On 7 June 2023, a Peak Downs CMW was adjusting backhoe forks to align the pin when their right hand came into contact with the pinch point area, causing their fingers to be crushed (refer Figure 5).

- On 12 June 2023, at Meandu Mine an excavator bucket was being prepared to be unloaded from a float using an 80T crane. A CMW was removing the restraint chains which held the bucket to the float when the crane commenced hoisting, and the bucket rolled trapping the CMWs right hand pointer finger between the load binder and chain. The CMW suffered crush injuries requiring surgery and a pin to be inserted.

- On 17 June 2023, at Carmichael Coal Mine while torquing pos 5 and 6 wheels on a Cat 796 electric drive haul truck, a CMW pulled the trigger of the Rad Gun jamming the little finger on their left hand resulting in a break of the bone between the first and second knuckle.

- On 20 June 2023, a CMW at Carmichael Coal Mine operating controls to insert another drill rod into the mast has had his fingers crushed between the swinging rod and a sharp steel edge. Left-hand middle and ring fingers have been crushed and both partially amputated.

- On 9 July 2023, a Commodore Mine CMW was working on a dozer when there was an unplanned movement of a load roller while fitting to the dozer, causing their right index finger to be wedged between the roller and track. The CMW suffered a fractured finger requiring specialist surgery.

- On 8 August 2023, an exploration CMW at Carmichael Mine was running a dummy probe down a bore hole, when it jammed. While re-winding wire line onto the winch, the dummy probe has come free and continued to drop into the hole. This resulted in the wire line running through operator gloved hand, causing severe laceration to their right ring fingertip which required corrective surgery (refer Figure 6).

- On 22 August 2023, during a scheduled dragline drag rope replacement at Capcoal Surface Coal Mine, a CMW has suffered a fractured finger which required surgery. The finger was fractured when it was stuck by a lug that separated from the end of the drag rope. The lug was welded to the end of the rope by the OEM to assist in drag rope replacements.

- On 22 August 2023, at Capcoal Surface Coal Mine whilst managing the dragline rope winch tugger, the CMW has caught their right-hand ring finger between the tugger rope and the winch sheave.

- On 24 August 2023, a CMW at Carborough Downs was holding a megabolt with his hand on the bolter head plate with their finger down the side of the bolt through the gripper jaws while he removed the grout cap. The bolter operator thought the CMW was clear and clamped the megabolt with the CMW s finger still in the gripper jaws, amputating the finger between the first and second knuckle.

- On 29 August 2023, at Peak Downs a CMW walking down the dig bench tripped and put their right hand out to brace the fall resulting in a compound fracture of their right pinkie finger.

Key issues

- 28 of 55 reported serious accidents year to date involve finger injuries. Additionally, a further 20 high potential finger injuries have been reported.

- The serious finger accidents reported resulted in injuries including amputations, severed tendons, de-gloving, crushing and severe lacerations.

- Of the 28 serious finger accidents reported, two-thirds involved CMWs completing maintenance tasks and a third involved CMWs operating plant or undertaking manual handling tasks.

- Approximately thirty percent of the serious accidents related to lifting, slinging or towing tasks.

- Reviews of investigation reports identified:

- inadequate job planning and provision of suitable tools.

- inadequate assessment of risks and implementation of controls.

- inexperienced persons undertaking tasks with inadequate supervision.

- poor communications between supervisors and CMWs and between CMWs undertaking the tasks.

- not following procedures, including failing to isolate and entering documented exclusion zones.

- lack of timely reporting.

Recommendations

All Site Senior Executives should:

- review and monitor the effectiveness of the mine job planning processes.

- review the effectiveness of site risk management processes, including application standards and compliance.

- review supervision and manning requirements for tasks.

- review and communicate site risk management, isolation, lifting and communication procedures.

- provide suitable tooling to eliminate the need for hands to be in any pinch points or crush zones.

- make sure procedures for tasks are developed, available and utilised.

- implement a “Hands Free” work initiative:

- Identify tasks where hands are involved and alternate methods that eliminate or reduce the need for hands to be in pinch/crush points.

- Establish work registers for “Hands Free” tasks with supporting procedures.

- Provide suitable tooling for "Hands Free" work.

- Communicate details of “Hands Free” work.

Every shift supervisor should:

- communicate and reinforce mine risk management processes.

- make sure risk management processes including SOPs, JSAs are supplied, followed and their use monitored.

- plan and adequately resources tasks.

- make sure jobs are planned and risk assessed (including review of risk assessments prior to work commencing) prior to proceeding. This includes making sure minimum site requirements have been met before work tasks commence.

- make sure specialised tools are maintained and provided to CMWs as required.

Every CMW should:

- follow mine risk management procedures. This includes completing on the job hazard analysis.

- utilise specialised tools to eliminate need for hands to be in any pinch / crush zone.

- where tasks being undertaken change from the plan, stop and re-evaluate risks following the mine procedures.

- actively practice risk management strategies with fellow workers.

Contact: Anthony Logan, Senior Inspector of Mines , +61 7 3199 8001 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database