Coal Inspectorate | Bulletin | No.206 V 1 | 05 December 2022

Learnings from confined space, spray painting event

What happened?

BACKGROUND / INCIDENT

On 25 April 2021, while working on a dragline shutdown and performing spray painting activities under a Confined Space Entry Permit, a Coal Mine Worker (CMW) became unresponsive and was rescued from inside the revolving frame of a dragline. A second CMW also had to be rescued after they re-entered the confined space to assist with the first rescue.

Safety Alert 393 (2 July 2021) was issued shortly after the incident to share findings from the initial investigation.

Since that time further investigative testing has been completed by RSHQ, to establish what the airborne concentrations of solvents were likely to have been in the working space, and what role the use gas detectors and the wearing of respiratory protection, contributed to this event. This involved:

- a full-scale re-enactment of the spray-painting task at SIMTARS, to simulate the incident and measure the airborne solvent concentrations present; and

- testing of the respiratory protection devices worn and gas detectors used during the incident, by the respective equipment manufacturers.

The purpose of this Safety Bulletin is to share the results and learnings from this further testing with industry, for consideration when developing risk controls to manage future spray painting tasks inside confined spaces on draglines, or other similar exposure situations.

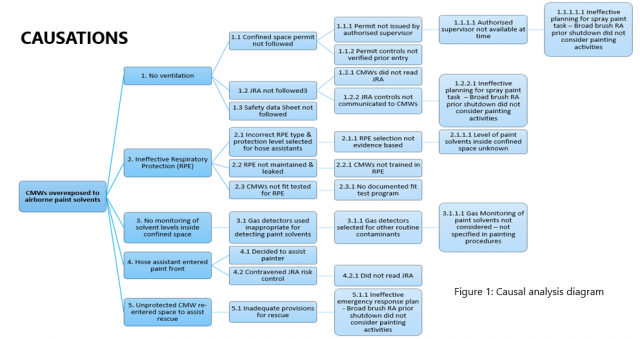

Findings from the investigation and subsequent testing results are reported and discussed. Recommendations for industry to raise awareness and prevent a reoccurrence are detailed. The causal analysis diagram can be accessed as Figure 1.

A technical paper detailing the test work completed and a summary of the results and their interpretation, is available as Attachment 1.

Key issues

FINDINGS FROM INVESTIGATIVE TESTING

Airborne concentration of solvents during spray painting

Tests undertaken during the incident re-enactment revealed:

- Measured concentrations in areas normally occupied by painters and occasionally by hose assistants, exceeded the immediately dangerous to life and health (IDLH) concentrations for all three solvent types, and the potential lethal concentration for toluene.

- Concentrations also exceeded the 10% Lower Explosive Limit (LEL) threshold, usually applied to trigger withdrawal and to control the flammability risks in confined space entry work, in accordance with AS2865:2009 Confined Spaces.

- The relative ratio of individual solvent concentrations measured in air, was generally consistent with the compositional ratio (% wt/wt) of individual solvent ingredients reported in the safety data sheet (SDS) for the paint.

Respiratory protection

The negative pressure half face respirators with A Class filters worn by the hose assistants, including the CMW who became unresponsive, did not provide an adequate level of protection from the solvent concentrations present. The organic A Class filters have limited capacity/ breakthrough time and the required filter replacement frequency, is difficult to estimate. They are also prone to paint contamination leading to leaking valves and the level of protection is subject to facial fit / facial hair/ and maintenance.

Air-supplied respirators using filtered air from a compressor and fitted with full facepiece or head covering, provided an adequate level of protection from the solvent concentrations present. These were worn by the operators conducting the spray painting.

Monitoring

Personal gas detectors (PGDs) including multi-gas types with electrochemical and catalytic bead sensors which are typically used in confined space entry work, are not suitable for the continuous monitoring of organic paint solvents in these situations, including for xylene, toluene and ethyl benzene. Alternative devices including photo ionisation detectors (PIDs) and/or colorimetric detector tubes, may provide a more accurate and reliable measure of instantaneous concentrations for control purposes.

Sampling tube extensions were found to act like solvent traps and prevented airborne solvent from reaching the detector. Remote sampling with extension tubes is not suitable for monitoring airborne organic solvents, in these situations.

Recommendations

As a result of these latest findings, the following recommendations are made in relation to the application of risk controls and monitoring, while spray painting with solvent based paint inside confined spaces within draglines, or other similar environments. These recommendations should be considered in addition to those provided previously in the Safety Alert 393.

- Ventilation mechanisms should be applied to confined spaces where spray painting with solvent based products, are applied. This ventilation should be designed in consideration of the rapid increase in toxic and flammable concentrations of solvent vapours resulting from relatively small application quantities and durations of exposure. The high vapour density of solvents and their propensity for layering on the floor should also be considered.

- Air-Supplied respirators should be selected in preference to powered air purifying (PAPR) and/or negative pressure respirators, which rely on regular cleaning, maintenance, facial fit testing, and particularly filtration performance and breakthrough capacity, in order to provide an adequate level of protection.

- Ignition sources should be removed from spaces where there is a potential for flammable concentrations of solvent vapours to occur. Paint surfaces should be earthed to prevent static charge build-up and the autoignition temperature of solvents and intrinsic safety requirements should be considered, when selecting portable equipment for use in these spaces (e.g. lighting, radios, personal gas detectors, mobile phones).

- Continuous monitoring of airborne solvent concentrations should be conducted inside the space, in addition to routine confined space monitoring (O2, CO, % LEL, Tox), to verify the effectiveness and adequacy of controls being implemented. These controls include ventilation, respiratory protection, and confined space entry and withdrawal restrictions at 5-10% LEL. The use of extension sampling tubes to facilitate remote monitoring should be avoided when monitoring for organic paint solvents, to prevent the loss of sample and underestimating the true concentration at the point of sampling.

- Clearance monitoring should be conducted to ensure airborne concentrations are suitable for occupancy, prior to re-entering the space after spray painting has stopped.

- Triggered action response plans (TARPs) should be developed to monitor conditions, and then escalate controls when required, to manage risk to an acceptable level.

Relevant procedures and practices within the mine’s safety and health management system (SHMS), which relate to the management of confined spaces, flammable and toxic gases, respiratory protection and hazardous chemicals, is to be reviewed to incorporate the recommendations listed above. These should also align with the following resources and references:

References and further information

- Standards Australia. AS2865:2009 Confined spaces. Sydney : Standards Australia, 2009.

- Standards Australia. AS/NZS 1715:2009 Selection, use and maintenance of respiratory protective equipment. Sydney : Standards Australia, 2009.

- Standards Australia. AS1716:2012 Respiratory protective devices. Sydney : Standards Australia, 2012.

- Workplace Health and Safety Queensland. Spray Painting and Powder Coating Code of Practice. Brisbane : Queensland Government, 2021.

Contact: Andrew Batterson, Inspector of Mines , +61 7 3199 8001 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database