Coal Inspectorate | Alert | No.404 V 1 | 20 December 2021

Unplanned movement of conveyor belt

What happened?

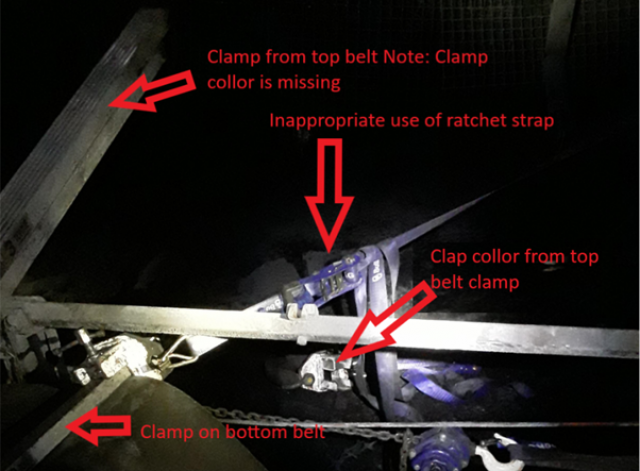

A crew was undertaking a belt retraction in an underground coal mine. The belt slipped through the belt clamp, and once released it travelled approximately 300 meters before folding up within the confines of the belt structure. This High Potential Incident could have resulted in serious injury to coal mine workers. Fortunately, there were no workers in travel path of the belt. There were no injuries resulting from the incident but significant learnings for industry.

How did it happen?

- There were insufficient chain blocks available on the job.

- Coal Mine Workers (CMWs) assumed that a ratchet strap could be used for the same purpose as a chain block.

- There was no procedure for conducting a belt retraction.

- The oncoming crew identified that the ratchet strap was unsuitable for the purpose.

- A chain block was found and installed on the belt clamp.

- When the chain block was tensioned, the locking collars pulled off the belt clamp bars, allowing the belt to slip through the clamp.

- Anchor points for chain blocks were randomly selected rib bolts, and no consideration was given to the angle of the load.

Key issues

- Ratchet straps are not an acceptable replacement for chain blocks.

- Anchor points were at inappropriate angles to the load.

- No procedure for the task.

- Ineffective job planning. A reliance on the crew developing a JSA. This was not specific or detailed.

- Ineffective hazard identification.

- Inadequate training in the use of lifting equipment.

Recommendations

All site senior executives should:

- Ensure that tasks scheduled for execution are planned in acceptable detail.

- Develop standard working instructions for belt retraction / extensions.

- Standard working instructions should consider installation of specific (fit for purpose) anchor points for each retraction / extension and not rely on a non-engineered or untested anchor points.

- Specify suitably engineered and rated tools and equipment for the task.

- Provide the right tools and equipment for tasks.

- Train CMWs in:

- the standard work instruction for belt retractions / extensions.

- the use of lifting equipment.

- hazard identification.

All CMWs should:

- Stop work where appropriate tools and equipment are not available.

- Ensure you are not in the line of fire.

- Ensure that they use appropriate tools and lifting equipment.

- Ensure that JSA’s are specific in steps through the task and detailed.

- Review the JSA in the event of any change in circumstances.

- Comply with standard work instructions.

- Install fit for purpose anchor points.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

Contact: Mick Scully, Inspector of Mines , 0459 878 917 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database