Mines safety bulletin

no. 185 |

28 February 2020 |

Version 1

Background

A serious accident involving the death of a Coal Mine Worker in 2019 has been investigated and the findings will be made available to industry. The findings from this incident and two other related incidents in other states have resulted in serious accidents. The findings from the last three incidents suggests that similar circumstances may exist across the industry requiring operators to audit their equipment and operating practices and ensure the lessons learnt are not forgotten. This bulletin addresses safety issues involved with three incidents and one potential incident:

First incident

Death of an excavator operator entangled by excavator access ladder

(Central Queensland 2019)

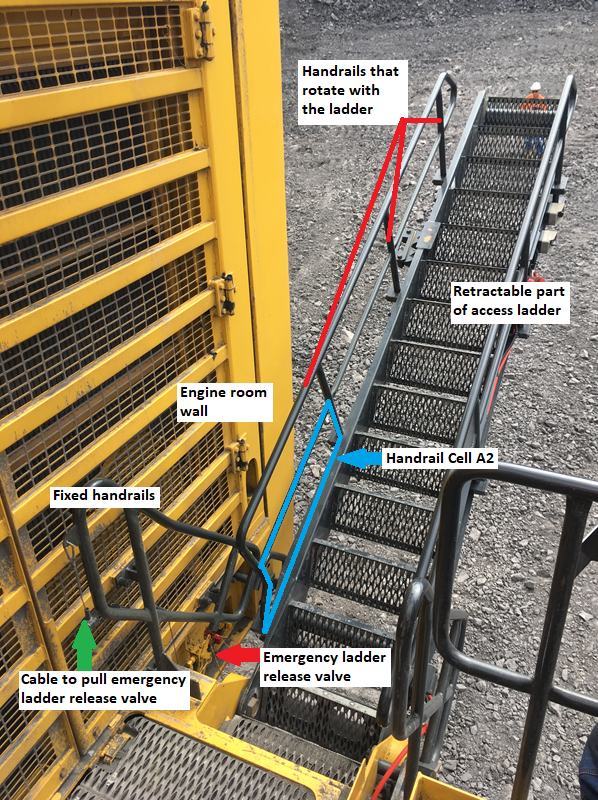

An operator was fatally injured when he became entangled between the movable part of an excavator’s access ladder and the wall of the engine room. (See Figure 1).

Findings

There were no witnesses to the accident, however it was determined that the most likely cause of the accident was that the operator tripped on the upper stairs or mid platform and became entangled within Cell A2 (Refer figure 2) of the handrails as the ladder was rotating down from the vertical position.

While there were several potential scenarios of how he became entangled, the evidence and analysis of data from the scene, indicated that when he tripped he inadvertently activated the emergency valve (E-Valve) positioned behind the rails (Figure 3).

It was identified that the E-valve had been accessible to operators and could be operated manually in a way not consistent with the requirements of the Original Equipment Manufacturer (OEM) operating manual. In addition, the valve could be rotated directly rather than by a pull cable installed for that purpose.

For routine lowering of the ladder, a set of controls, requiring two hand operation, was positioned a few meters away from the hazard on the mid stairs landing. The findings of the investigation are that these controls were not activated to fully lower the stairs.

Recommendations

The Queensland Resources Regulator recommends the following:

- OEM & mine operators must consider the hazards created by moving ladder parts during the design phase and introduction of plant to site.

The design of access ladders where crush zones are created when the rotating parts pass stationary parts should be reviewed and controls implemented where risk is identified.

The excavator that had been involved in this incident was subsequently modified. Mesh inserts were installed on the rotating handrails to prevent persons accessing the E Valve and covers installed over the E Valve(See Figure 4).

- Apply the hierarchy of controls to the design of the E-valve on mobile equipment.

The procedure, administrative control, required the ladder to be lowered from a safe location. However, it was physically possible to access the E-valve directly.

Engineering controls should be applied to isolate the valve and prevent it from being accessed intentionally or inadvertently.

- Notification to standards

Regulator will inform Standards Australia of findings of this investigation for future consideration in future versions of standards for heavy vehicle access systems.

- Identify and rectify trip hazards

Review the mines excavator and other equipment access design to identify and rectify possible trip hazards.

- Review power supply to the vehicle health monitoring system

It is recommended that if a unit of mobile equipment is fitted with a vehicle health monitoring system, as was the case in this incident, power continues to be supplied to the system after the application of an emergency stop switch.

- Maintain three points of contact

Communicate the findings of the investigation to coal mine workers including the importance of effectively maintaining three points of contact whilst using ladders or stairs on any building, plant or equipment.

Second incident

No emergency access to excavator - (Central Queensland 2019)

Most large mining excavators have a retractable ladder that provides access to the operator’s cabin and maintenance areas. During operations, the ladder is raised and the machine cannot be boarded.

Designs vary, but for normal operation, the movement of the ladder (up or down) is typically controlled with switches. For emergency lowering, a hydraulic valve accessible from ground level or on board is opened. (Figure 5).

Findings

- Observations by the Inspectorate found that on some models of excavator the ladder cannot be lowered with the emergency valve from ground level unless the engine is running.

- Rescuers from ground level would have difficulty accessing the machine in a timely manner to provide assistance to a person in case of an emergency whereby.

- The operator is incapacitated

- The access ladder is raised and is the only means of access

- The engine is not running.

The Queensland Resources Regulator recommends the following:

- Inspect each unit of equipment with a retractable access ladder to determine whether the above configuration applies

- Test emergency lowering in all modes of operation:

- From on board / from ground level

- With engine running / With engine off

- Review design and commissioning risk assessment and modify to reflect findings of test program.

Third incident

Shovel operator fatally injured by retractable ladder (Western Australia 2018)

A shovel operator was fatally injured when crushed between a retractable hydraulic access ladder and a handrail as he was investigating the cause of an engine power loss. (See Figure 6)

Circles indicate where the accident happened, showing the ladder in the final (left) and upright (middle) positions with the handrail, platform and emergency shutdown (A) and ladder (B) switches.

Findings

There were no witnesses to the incident.

It appears that the operator was standing to the left of the ladder, attempting to reset the emergency shutdown switch A, which was outboard of the railing. He activated the nearby ladder pull-down wire instead. He was crushed against a stationary handrail when the ladder rotated down.

Recommendations

- The following safe systems of work are recommended to mining operations to assist in the safe operation of shovels and excavators:

- Conduct an audit of shovels and excavators on site to identify all configurations of actuated access ladders and stairways that could present a crush hazard to workers accessing emergency switches.

- Note: Pay particular attention to machines with rotating ladders and emergency pull-wire switches that could be activated inadvertently, either by personnel or by material falling against the machine.

- Conduct a risk assessment of these potential crush hazards and implement appropriate controls (e.g. safe positioning of switches, clearly labelling all switches and switch positions, providing adequate lighting for all tasks).

- Review standard operating procedures for the operation of shovels and excavators to confirm they include operation and reset of emergency switches.

- Train those using and accessing shovels and excavators in the reviewed standard operating procedures.

Fourth incident

Mine worker injured after falling from grader access ladder (New South Wales 2014)

A coal mine worker at an open cut coal mine sustained spinal injuries when he fell from an access ladder on a grader after it had unexpectedly rotated.

Findings

The operator was cleaning the grader windows and was standing on the access ladder in the lowered position. When he closed the door, the ladder unexpectedly rotated to the raised position. The operator fell head-first onto the ground, sustaining spinal injuries.

When the door closed, a series of interlocks activated, causing the ladder to rotate. More information is available in Safety Alert SA14-05 by the New South Wales Government. It can be viewed at

Recommendations

(As SA14-05)

- Mine operators should consider auditing retractable ladder systems installed on mobile equipment to ensure they are installed and operating in accordance with the ladder manufacturer’s recommendations.

- Mine operators should review their risk assessments for mobile equipment fitted with retractable ladder systems to ensure the hazards associated with these systems have been identified, and appropriate controls have been established.

- Mine operators should review operating, maintenance and training procedures for mobile equipment fitted with retractable ladder systems to ensure the controls identified in the risk assessments have been implemented.

- Mine operators should ensure they have a rigorous process for introducing new equipment to site, that includes obtaining and reviewing all relevant safety documentation, including design risk assessments, before mobile equipment is placed into service for the first time.

- Mine operators should ensure that a mine specific operations and maintenance risk assessment is carried out for new mobile plant, and the controls arising from this assessment implemented prior to the introduction of equipment.