Mineral Mines & Quarries Inspectorate | Alert | No.398 V 1 | 08 October 2021

Safe use of quick hitches on excavators

What happened?

A worker was seriously injured while performing maintenance work on the bucket of a 30-tonne excavator. The bucket suddenly detached from its quick hitch, swinging about 1.5 metres before it fell to the ground. The worker was knocked over by the bucket, hitting their head on the concrete floor and sustaining a crush injury to their leg.

How did it happen?

The incident is under investigation, however the preliminary finding are:

- a bolted cutting edge on an excavator bucket required changing

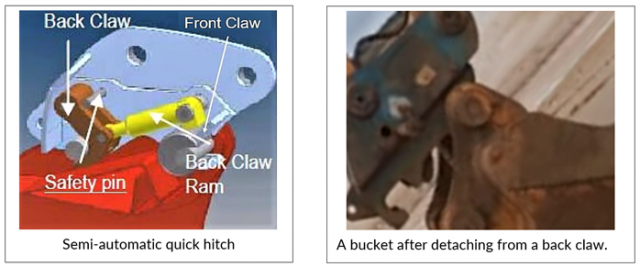

- the bucket was attached to the excavator and held in place by a semi-automatic quick hitch

- the safety pin to prevent accidental detachment of implements from the quick hitch was not installed

- the bucket was positioned in the air, with the cutting edge ~500mm above the concrete floor, the bottom of the bucket and cutting edge approximately vertical

- the engine of the excavator had been shut down

- the hydraulic ram on holding the back claw on the semi-automatic quick hitch failed to hold the bucket in place, which resulted in the bucket being released

- the worker was standing at the front of the bucket, between the bucket and excavator cab when the bucket released.

Key issues

The following key issues have been identified:

- There have been numerous occasions when excavator buckets have detached unexpectedly and often with serious consequences.

- The critical controls necessary to prevent this incident from occurring were absent or ineffective, including:

- existing energy sources were not isolated - there was a reliance on hydraulic systems to hold the boom and bucket in position (ineffective)

- the site had a procedure for undertaking this task, however the bucket at the time of the accident, was not placed on a firm, stable, level surface to ensure it could not inadvertently move or fall (absent)

- work was being undertaken within the drop zone of a suspended load (ineffective)

- the safety pin to prevent accidental detachment was not installed (absent)

- the safety pin available in the excavator was not consistent with the quick hitch manufacturer’s specification (ineffective).

Recommendations

All mine operators and site senior executives should:

- ensure that where maintenance work is to be undertaken on equipment, all energy sources are identified and isolated. This must include consideration of potential, stored and gravitational energy

- provide excavators and backhoes fitted with fully automatic quick hitches, which don’t require the operator to insert a safety pin to prevent the quick hitch releasing and implements from detaching

- ensure that in the circumstance where fully automatic quick hitches are not provided, safety pins are always utilised

- ensure all quick hitch attachments have the original equipment manufacturers safety system

- ensure that workers are trained, assessed and a record kept of them demonstrating the safe fitting of attachments prior to operating plant

- provide adequate supervision and monitoring to ensure that controls to manage the risk of hazards are implemented and effective.

In all circumstances, workers should:

- not undertake activities or tasks unless they understand the hazards present and the controls that must be present and in place to manage the risk from these hazards

- not place themselves in situations that are solely reliant on hydraulic systems for their safety.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

References and further information

- SafeWork NSW Position Paper-Supplying, installing, and using quick hitches on excavators or backhoes.

- AS 4772: 2008 Earth-moving Machinery – Quick Hitches for Excavators and Backhoe Loaders.

- AS1418.8 – 2008, Cranes, hoists, and winches – Special purpose appliances.

- ISO13031 – 2016, Earthmoving machinery – Quick couplers.

Contact: Jon Smith, Inspector of Mines , +61 7 3330 4251 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database