Coal Inspectorate | Bulletin | No.203 V 1 | 27 June 2022

Lifting and Rigging Incidents

What happened?

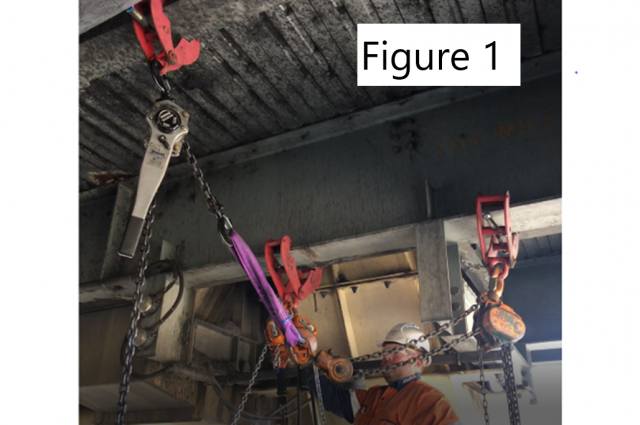

Recent high potential incidents and serious accidents reported to the mines inspectorate have raised concerns about lifting and rigging activities, especially where chain blocks and lever hoists were used and / or loads were being drifted (refer Figure 1). Drifting loads refers to moving loads horizontally while being suspended. The high potential incidents reported have involved coal mine workers (CMWs) being struck, or nearly struck by loads that were being lifted, lowered, or suspended. Incidents reported include:

Incident 1. On 16 June 2022, workers were replacing a crushing and screening plant conveyor belt when a rope snapped and struck a worker in the face. A worker suffered serious injuries including the loss of an eye.

Incident 2. On 25 March 2022, CMWs were dismantling conveyor equipment underground. This required the movement of a suspended load of an estimated four tonnes, using block and tackle, lever hoist (cumalong), and slings. The load shifted during the activity and resulted in fatal injuries to a coal mine worker. The investigation into the nature and cause of this incident is ongoing.

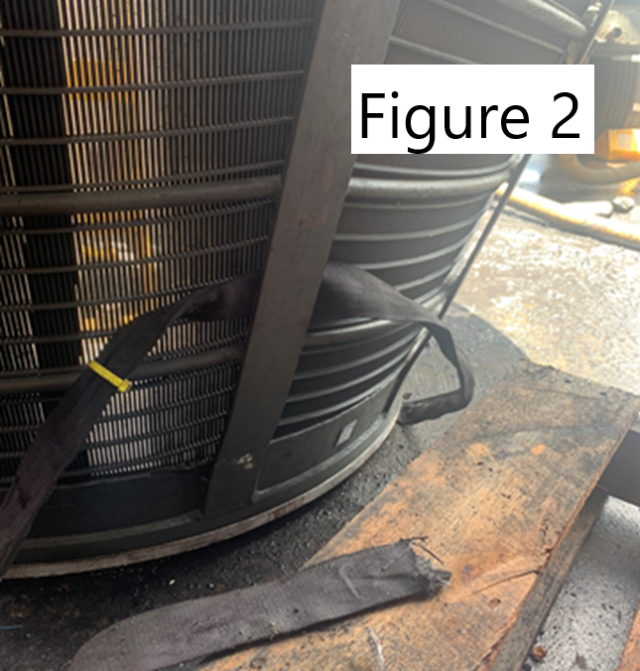

Incident 3. On 6 December 2021, while lifting a new coarse coal centrifuge basket from the ground floor of the coal handling and preparation plant (CHPP) to the centrifuge floor, the soft sling failed, resulting in the basket falling to the ground (refer Figure 2). The area was not barricaded, and available lifting jigs not utilised.

Incident 4. On 11 October 2021, a CMW was replacing a deflector shield on a transfer chute. Whilst trying to restrain the load manually, he fell from a height of approximately 3-4m and suffered serious injuries, including leg injuries.

Incident 5. A slew crane was lifting a concrete panel from a horizontal to a vertical position. The tilt panel pivoted towards the crane, momentarily trapping the CMW (dogman) between crane and the tilt panel. The CMW suffered serious crush injuries, including a fractured pelvis.

Incident 6. A CMW was replacing a vibrating motor on a dewatering screen in a CHPP. The 270kg motor was rigged using one, 3 tonne cumalong and two, 1 tonne cumalongs with beam clamps. The vibrating motor fell while being manoeuvred and the CMW suffered a compound leg fracture when struck by the falling motor.

Other incidents reported

The following is a partial list of high potential incidents reported which did not result in a serious accident:

Uncontrolled movement whilst lifting an excavator boom cylinder: Whilst being lifted for installation into an excavator, a boom hydraulic cylinder slipped in its lifting chains. It did not fall to the ground and was operating within an exclusion zone.

Unplanned movement of a Reject Bin Chute: While removing a reject bin chute by crane for repairs, the chute released suddenly and swung uncontrolled. Two CMWs in a nearby EWP were out of the line of fire and not injured.

Crush injury whilst replacing a rear dump truck spindle: Whilst installing a spindle unit on a haul truck, a CMW sustained a crush injury to the right-hand little finger when it became caught between a fibre sling and a wheel stud. The CMW was adjusting the sling when it came under tension.

Lifting lug failure when replacing a wheel strut: Two CMWs were replacing a wheel assembly strut on a rear dump truck when a lifting lug failed and allowed the cylinder to topple to the ground.

Dragline tub swing rack eye bolt failure: A failed eye bolt ejected 18m when rotating a swing rack. CMW's deviated from the set lifting plan as stated in the job safety analysis.

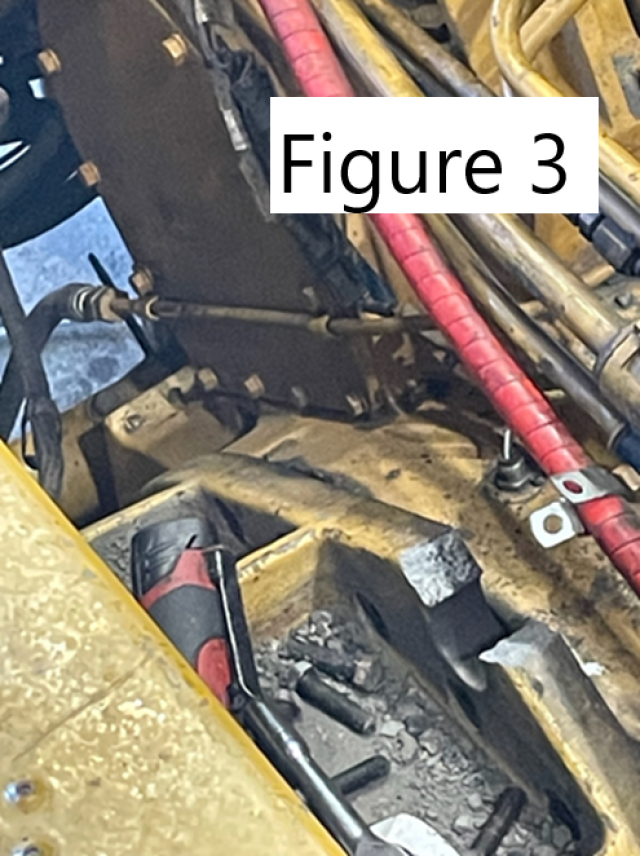

Lifting lug failure: Two CMWs were removing a torque converter from a haul truck. Whilst lifting the load using a 1.5t gantry crane, the cast lifting lug on the torque converter failed (refer Figure 3). The torque converter did not move, but the lifting lug shattered - with one piece (220g) found 5m from the truck.

How did it happen?

All lifting operations can pose significant risk, including fatalities to people. Operators report that many lifting and rigging incidents have occurred during what are perceived as low risk operations.

Lifting and rigging tasks in underground mines, CHPPs, and maintenance activities may involve complex lifts involving multiple lifting devices, such as chain blocks & lever hoists and drifting of loads (refer Figure 1).

Failure of lifting equipment can potentially result in a dropped load or object, while failures of rigging equipment can potentially result in an uncontrolled vertical or horizontal movement of the load or equipment.

Review of the incident investigations identified multiple causes, not all of which were relevant to each incident. Contributing causes included:

- Mine standard operating procedures (SOPs/MOPs/standards) including those for selecting, maintaining and using lifting plant operations were not followed.

- Work planning, including the design and planning of lifting activities was inadequate.

- Risk based lifting/rigging plans were inadequate, incomplete, or not completed.

- An approved lifting plan was changed, and the review and approval processes not followed.

- Supervisors who did not have relevant competency, experience, or understanding of the lifts signed off lift plans and did not inspect the site prior to the lift.

- CMWs were positioned inside exclusion zones when loads moved in an uncontrolled manner.

- Failed lifting components were found to have been overloaded. Crane loadcells were not monitored.

- Inappropriate lifting equipment was utilised. Available lifting jigs and tools were not utilised.

- Poor slinging practices.

- Mine site training and competency requirements did not adequately assess individuals’ capabilities and experience to undertake specific lifting tasks - particularly complex lifts.

Key issues

Considerations when selecting, maintaining and using lifting plant

Considerations should be given to:

- Reviewing lifting equipment management plans to ensure all activities using lifting equipment are appropriately addressed, including routine and non-routine activities and simple and complex lifts. In many applications a complex lift may require multiple lifting devices, slinging, and drifting loads. Reviews should include crane operations as well as other lifting devices like chain blocks and lever hoists.

- Design of installations considering the life cycle of the plant or equipment from construction, through commissioning, operation, maintenance, and decommissioning. Foreseeable requirements for lifting, like pulley and drive replacements of underground conveyor installations and CHPP components should be considered in the design.

- Completing lifting or rigging plans for every lifting or rigging operation (routine and non-routine). The lifting and rigging plan requirements should be detailed in the mine’s Safety and Health Management System (SHMS). Consider implementation of site-specific lifting forms or permits. Simple tasks may only need a basic plan, but infrequent or complex lifting or rigging operations may require significant engineering.

- Seeking appropriate competent engineering advice in the design and selection of equipment when conducting non-routine and complex lifting tasks.

- The rating and yield load of all components, including the connection points, must be considered in the design of the lift. Additionally, consider the structure supporting the connecting point. This may be a building structural beam, or roof bolts/elephants’ foot in an underground mine. Integrity of underground coal mine rock bolts should also be considered, and this may require the implementation of pull tests and not relying on single points of attachment.

- Safe standing / exclusion zones should be established for lifting and landing areas and along the load’s travel path to account for component failures and dropped objects. Access to these areas should be restricted to people directly involved with the work. All risks in relation to the work should be taken into consideration when determining the size of exclusion zones. Alternate lifting and work methods should be considered if a CMW needs to be within the exclusion zone.

- Selection of appropriate lifting equipment for the specific lifting application. For example, avoid selecting lifting equipment that requires the operator to stand in fall or exclusion zones.

- Review lifting training course content, including practical assessments, as being suited to the lifting tasks being undertaken. Ensuring training competencies and licences adequately address transfer or load shifting. People responsible for lifting activities should be able to demonstrate competence in the specific task to be undertaken.

- The provision of adequate information, training, instruction and supervision to protect workers from risk when carrying out lifting tasks.

Recommendations

Site Senior Executives should:

- Review the mine SHMS, including SOPs, for selecting, maintaining, and using lifting plant and ensure specific risk-based controls for use of chain blocks, drifting loads and complex lifts are included and documented.

- Ensure the SHMS provides effective preventive critical controls for lifting and managing suspended loads, to prevent uncontrolled movement of suspended loads and to ensure CMWs will not be in the line of fire.

- Implement procedures to verify consistent application of all lifting management plan requirements.

- Verify that supervisors and CMWs conducting lifting activities have the appropriate demonstrated competencies relevant to the tasks to be undertaken and that they are familiar with and understand the attributes of the various rigging & sling arrangements.

Supervisors should:

- Ensure requirements of the mine's SHMS and lifting management plan are followed and adhered to in their area of responsibility.

Coal Mine Workers must:

- Understand and comply with site requirements. Any changes to an approved lifting plan must follow site change procedures.

References and further information

- Fatal accident underground working with suspended load: RSHQ Safety Alert 406 - 27 March 2022

- Cranes and lifting equipment a serious injury risk: WorkSafe Qld - July 2021

Contact: Anthony Logan, Senior Inspector of Mines (Mechanical) , 0477 373 213 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database