Coal Inspectorate | Alert | No.395 V 1 | 16 August 2021

CHPP pump suction pipe dislodges resulting in a serious injury

What happened?

On the 21 July 2021 coal mine workers were undertaking maintenance work on a pump in a coal handling and preparation plant. During the process the suction line, including the sump isolation valve released from the sump wall under pressure. A worker was impacted by the expelled components suffering a serious injury. The expelled pipework, pump and sump are shown in Figure 1.

How did it happen?

The incident is under investigation; however, it is understood that the following occurred:

- Coal mine workers were in the process of changing a pump in a coal handling and preparation plant.

- The suction valve and pipe from the sump was isolated. The sump contained fluid.

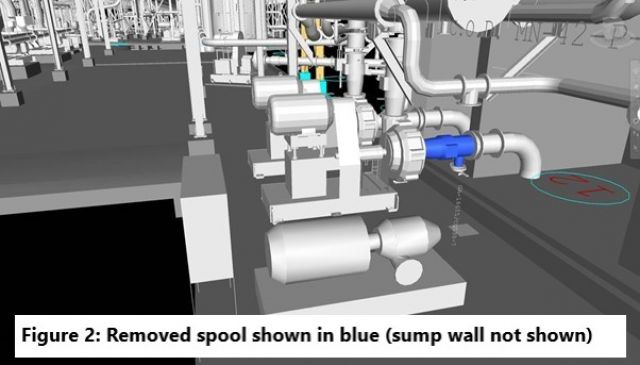

- At the time of the incident a pipe spool had been removed as planned. The pipe spool which had been removed is shown schematically in Figure 2.

- The injured worker was standing between the pump and the suction pipe protruding from the sump wall.

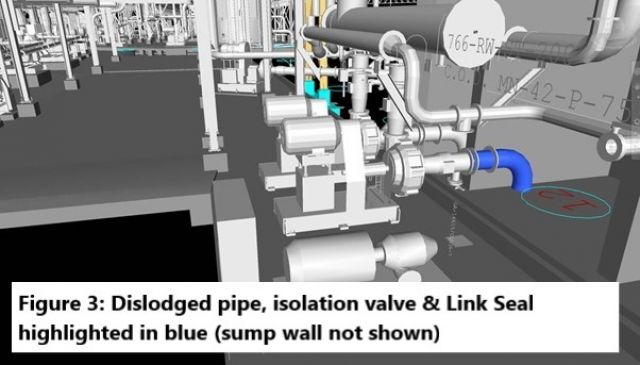

- The isolation valve, piping and Link-Seal released from the sump wall, impacting the worker and pushing him against pump. The pipework ejected from the sump is schematically shown in Figure 3.

- Emergency response procedures were initiated by the work crew and the worker was removed to a safe location.

Key issues

The following key issues have been identified:

- The worker was in the “line of fire” when the Link-Seal and pipework failed.

- The sump contained fluid.

- The suction pipe had been retained in the sump wall by a Link-Seal.

- Link-Seal modular seals are penetration type seals. They are not intended to be a structural support.

- Suction pipework was not supported or restrained by other means.

The investigation into the incident is ongoing and further issues may be identified and communicated.

Recommendations

SSEs must:

- Complete an audit of site plant and identify where Link-Seal type seals or similar are installed.

- Make sure that Link-Seals are installed as per the Original Equipment Suppliers requirements.

- Make sure that pipes and valves are adequately supported and restrained. That Link-Seals are not relied on for structural support. Engineered supports and restraints should be used.

- Review and update risk assessments and associated procedures ensuring risks associated with all stage of the life-cycle of the seal and associated components in the system (eg pipes, valves, seals) are considered. This should include foreseeable installation, operation and maintenance scenarios.

- Ensure the failure of pipework and seals has been adequately considered. The potential for serious harm to workers in the “line of fire” must be considered and controls implemented to minimise risk to worker.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

Contact: Anthony Logan, Senior Inspector of Mines - Mechanical , +61 7 3199 8013 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database